It's almost January - the start of the Spring 2011 college semester. With my impending graduate school coursework comes the need for a laptop computer. I have been to several stores during the past several weeks, shopping price v.s. features. The college book store offers what seems like "sweetheart deals" on Dell laptops; you simply pick out the recommended machine based on the academic department for your course of study. While this seems like an easy option, and the package had lots of goodies thrown in, I was still put off by the $699 price tag. I ask myself "Do I really need all this or will a $349 Acer at Wal-Mart do as well?" Since I really don't yet know how much computer I really need, I decided to get advice from my instructor based on the actual demands of the curriculum before making a purchase.

One brand I have ELIMINATED is Dell - I will NOT have one of these unless some kind soul gives me a free one. Even then, I'd likely sell it on eBay and buy something else. Here's why:

A Descent Into (D)ell:

Recently, a neighbor asked me to look at his laptop and see if I could repair it. His girlfriend had dropped the machine and it had landed directly on the charger power plug, while it was still connected. This damaged the DC power connector on the laptop and the unit would no longer charge or even run off the AC adapter.

To make a very long story short

I replaced the connector, reassembled the laptop, and it still won't work from the AC adapter. Voltage checks with a DVM show all the connections to be good and that the AC adapter is supplying the proper voltage. The computer runs just fine from the battery; problem is right now there is no way of recharging the battery - and said battery is nearly depleted. On doing some online research, I found out Dell uses a special ID chip in all its AC power adapter/chargers - as well as its batteries. This ID chip "talks" to one located on the motherboard. If the computer does NOT recognize the power adapter/charger as a genuine Dell artifact, the machine will not charge the battery and may not even run, as in the case of my neighbor's unit. Same with the battery - if the computer does NOT recognize the battery as a genuine Dell artifact, it will not turn on.

During the fall, my neighbor's DC power connector got shorted out as a result of being smashed. Evidently this resulted in part of the ID system being damaged and disabled.

For more detailed technical information see the following links:

http://getsatisfaction.com/dell/topics/dell_laptop_wont_recognize_power_adapter_or_charge_battery

http://www.laptops-battery.co.uk/blog/dell-ac-power-adapter-type-cannot-be-determined-solution/

But wait, It gets even worse.

From my research, I've found that these chips fail regularly in both the AC charger units as well as the motherboards. MANY folks have been forced to buy replacement batteries and chargers because their ID chips and/or the three-pin charger power connectors got loose enough where the data line didn't make good connection any more. Dell's solution - buy new accessories and if the problem persists, replace the motherboard, a $330 dollar item as quoted to me by Dell tech support.

Several web sites have commented on the poor engineering and flimsy construction of these things but Dell continues to make them the same way.

While some other laptops also have ID chips in the batteries, I've found the Dell machines seem to garner by far the most complaints online.

A Possible Workaround

If you are in my neighbor's situation and don't want to or can't afford to shell out several hundreds of dollars to fix the problem, there is an external charger that will communicate with the battery's ID chip and thus be able to charge it out of the laptop.

http://www.laptop-junction.com/toast/content/standalone-laptop-battery-charger-dell-laptops

This is definitely a kluge, since you cannot simply plug the machine into AC power when the battery gets low and keep working. However, for those who cannot afford to replace the motherboard, or their entire machine, this is at least a way to retain partial use of it until a later time.

Conclusion

For those of us in the market for a new laptop, Let the buyer beware! If I can, I will select a machine that does NOT use multi-pin power connectors and ID chips for batteries and chargers. This, by itself, eliminates a potential source of unreliability in something I will have to depend on to get work done.

I also would like the option of running mine on off-grid power WITHOUT having to resort to a power inverter to feed the AC charger. Clearly a Dell would NOT be compatible with a home made battery supply or a solar panel without major internal hacking.

In view of the fragility of laptops and how difficult they generally are to repair, I highly recommend buying a 2-3 year extended warranty if the cost of such is no more than 1/3 of the everyday price of a comparable new machine. Even a cheap, "bottom of the barrel" laptop is a big enough investment that one would want to use it for at least 3 years - far longer than the 90 day to 1 year that most manufacturer's warranties last.

Sunday, December 26, 2010

Friday, November 19, 2010

Using gcc and g++ To Compile Programs In A LINUX Or Windows Environment

Many LINUX and most UNIX users are familiar with the gcc and g++ compilers. GCC stands for the "GNU Compiler Collection". GCC supports C, C++, JAVA, and a few others. GCC and g++ are available for free for most distributions of LINUX and UNIX. Many folks have used these utilities for both school projects as well as actual production development. The "GNU Compiler Collection" is ideal for developers, students, hobbyists, or anyone else wanting to work with or learn C/C++, JAVA, or Fortran on a shoestring and NOT shell out major funds for a commercial product. CygWin g++ and MinGW are designed for Windows machines; I've posted a link concerning this near the end of this post.

The gcc utility supports C, whereas g++ also supports C++.

GCC may be operated either from the command line or via a graphical IDE (Integrated Development Environment). Some folks also use it from within the vim or emacs text editors. I will cover the Code::Blocks IDE environment in a future post.

These are operated from the command line using commands such as the following:

gcc file.c

or

g++ file.c

Various command line switches such as -o, -g, ... tell it to save to a specific output file name, use the gdb debugger, etc.

The gcc and g++ compilers, by default, output to a file named a.out, unless you use the -o switch.

To compile a program and output to a filename of your choosing, such as "My_File", you would do the following:

gcc file.c -o My_File

To quickly test my compiler, I typed out the ever popular "Hello World" program in my text editor as shown below:

#include

main() {

printf("Hello from Karl's Lab!\n");

return 0;

}

and saved it as "Hello_Test.c" in my home directory. I wanted an output file called "Hello_1". I also wanted debugger information. Here's the command I used:

gcc Hello_Test.c -g -o Hello_1

The "-g" switch activated the gdb debugger; the -o Hello_1 part told it to name the output file "Hello_1"; "the "Hello_Test.c" part told it the name of the source file to be used.

When I typed "Hello_1" without the quotes at the command line, I received the following output:

Hello from Karl's Lab!

See a Compiler error:

In C, you must use the ";" symbol at the end of a statement. I wanted to see how gcc responds to an actual error, so I removed the ";" symbol from the "printf" line in the code snippet above, then saved and compiled the code as before. Here's the message it returned:

Hello_Test.c: In function ‘main’:

Hello_Test.c:7: error: expected ‘;’ before ‘return’

The first line of information shows the function - "main" - the error occurred in. The second line of output shows which line number the error occurred in and there is a ";" symbol missing in the code. While the actual typo was in line 4 of the code, the 'return' statement at line 7 is where the compiler errored out. With this output, you are at least given somewhere to start in trouble-shooting your code.

See the gdb debugger work:

Suppose your working directory is /home/mike/c_progs, and your executable is My_File. The command you would enter at the command line is:

gdb /home/mike/c_progs/My_File

You will get something like the following:

Copyright (C) 2008 Free Software Foundation, Inc.

License GPLv3+: GNU GPL version 3 or later

This is free software: you are free to change and redistribute it.

There is NO WARRANTY, to the extent permitted by law. Type "show copying"

and "show warranty" for details.

This GDB was configured as "i386-redhat-linux-gnu"...

(gdb)

At this (gdb) prompt, RUN "My_File" by typing "r" (without quotes).

(gdb) r

Starting program: /home/mike/c_progs/My_File

Hello from Mike!

Program exited normally.

This shows the program's output (Hello from Mike!), as well as that it executed without any errors or warnings.

When you are finished working, EXIT the gdb prompt by typing "q" without the quotes at the (gdb) prompt. This exits the debugger and returns you to the UNIX shell prompt.

Here are some good links on using gcc and g++ :

GCC's Homepage - Look here for the manuals to whatever version of gcc you have.

http://gcc.gnu.org/onlinedocs/

http://www.network-theory.co.uk/docs/gccintro/

Some good info for getting g++ for a Windows machine:

http://cocoon.cs.odu.edu/cocoon/~cs252/open/yourOwnCompiler/allPages.html

Here are some links to a good tutorial on the gdb debugger:

http://heather.cs.ucdavis.edu/~matloff/UnixAndC/CLanguage/Debug.html#tth_sEc3.2.1

and

http://www.cs.cmu.edu/~gilpin/tutorial/

The GCC Homepage:

http://gcc.gnu.org/

The gcc utility supports C, whereas g++ also supports C++.

GCC may be operated either from the command line or via a graphical IDE (Integrated Development Environment). Some folks also use it from within the vim or emacs text editors. I will cover the Code::Blocks IDE environment in a future post.

These are operated from the command line using commands such as the following:

gcc file.c

or

g++ file.c

Various command line switches such as -o, -g, ... tell it to save to a specific output file name, use the gdb debugger, etc.

The gcc and g++ compilers, by default, output to a file named a.out, unless you use the -o

To compile a program and output to a filename of your choosing, such as "My_File", you would do the following:

gcc file.c -o My_File

To quickly test my compiler, I typed out the ever popular "Hello World" program in my text editor as shown below:

#include

main() {

printf("Hello from Karl's Lab!\n");

return 0;

}

and saved it as "Hello_Test.c" in my home directory. I wanted an output file called "Hello_1". I also wanted debugger information. Here's the command I used:

gcc Hello_Test.c -g -o Hello_1

The "-g" switch activated the gdb debugger; the -o Hello_1 part told it to name the output file "Hello_1"; "the "Hello_Test.c" part told it the name of the source file to be used.

When I typed "Hello_1" without the quotes at the command line, I received the following output:

Hello from Karl's Lab!

See a Compiler error:

In C, you must use the ";" symbol at the end of a statement. I wanted to see how gcc responds to an actual error, so I removed the ";" symbol from the "printf" line in the code snippet above, then saved and compiled the code as before. Here's the message it returned:

Hello_Test.c: In function ‘main’:

Hello_Test.c:7: error: expected ‘;’ before ‘return’

The first line of information shows the function - "main" - the error occurred in. The second line of output shows which line number the error occurred in and there is a ";" symbol missing in the code. While the actual typo was in line 4 of the code, the 'return' statement at line 7 is where the compiler errored out. With this output, you are at least given somewhere to start in trouble-shooting your code.

See the gdb debugger work:

Suppose your working directory is /home/mike/c_progs, and your executable is My_File. The command you would enter at the command line is:

gdb /home/mike/c_progs/My_File

You will get something like the following:

Copyright (C) 2008 Free Software Foundation, Inc.

License GPLv3+: GNU GPL version 3 or later

This is free software: you are free to change and redistribute it.

There is NO WARRANTY, to the extent permitted by law. Type "show copying"

and "show warranty" for details.

This GDB was configured as "i386-redhat-linux-gnu"...

(gdb)

At this (gdb) prompt, RUN "My_File" by typing "r" (without quotes).

(gdb) r

Starting program: /home/mike/c_progs/My_File

Hello from Mike!

Program exited normally.

This shows the program's output (Hello from Mike!), as well as that it executed without any errors or warnings.

When you are finished working, EXIT the gdb prompt by typing "q" without the quotes at the (gdb) prompt. This exits the debugger and returns you to the UNIX shell prompt.

Here are some good links on using gcc and g++ :

GCC's Homepage - Look here for the manuals to whatever version of gcc you have.

http://gcc.gnu.org/onlinedocs/

http://www.network-theory.co.uk/docs/gccintro/

Some good info for getting g++ for a Windows machine:

http://cocoon.cs.odu.edu/cocoon/~cs252/open/yourOwnCompiler/allPages.html

Here are some links to a good tutorial on the gdb debugger:

http://heather.cs.ucdavis.edu/~matloff/UnixAndC/CLanguage/Debug.html#tth_sEc3.2.1

and

http://www.cs.cmu.edu/~gilpin/tutorial/

The GCC Homepage:

http://gcc.gnu.org/

Labels:

C,

C compiler,

C programming,

C++,

CygWin g++,

g++,

gcc,

LINUX,

MinGW,

Windows

Monday, November 15, 2010

Test of Ubuntu 10.10 "live" CD

Yesterday I tested Ubuntu 10.10 - Maverick Meerkat "live" CD release.

After downloading the iso file and burning it to CD, I booted my dual core 1.8 MHz machine to it. It took about 2.5 minutes to boot from the P.O.S.T. screen to the desktop. As I said in my last post, this is about typical of my experience with a "live" CD boot.

Ubuntu 10.10 auto-detected my HP printer and prompted me to install the HPLIP utility and drivers. Very cool!

Other observations:

1) This distribution has Open Office

2) Screen capture applet shows in the screen captures here - I suspect this is a bug

3) NO Gnu Image Manipulation Program (GIMP)

4) The gcc compiler does come with the "live" CD

5) The buttons to close, expand, or reduce active windows have been moved to the upper left-hand side of the windows. Why Canonical, the makers of Ubuntu, decided to do this, I don't know. I'm used to these functions being in the upper right hand corner of the window and prefer it that way.

6) Still the same GNOME desktop - the "Unity" desktop we've been hearing about lately is to occur in an upcoming "11" release.

7) As with Fedora 14, setting up my broadband access was a snap. A browser window may be seen in the following screenshot

I did not bother to try it on my 800 MHz Pentium III machine due to hardware issues.

You can get your own copy of Ubuntu 10.10 here:

www.ubuntu.com

Thursday, November 11, 2010

Test Of Fedora 14 'Live' CD Release

Last night, I decided to stay up late and try out the Fedora 14 live "Laughlin" CD release. I burned a CD from the iso file and booted my dual core machine to it. This machine is 1.8 MHz with 1 GB of RAM. Boot time was 1 minute 45 seconds. About typical in my experience for a CD ROM "live" run - booting from a CDROM and running the system entirely in RAM causes a bunch of latency you don't get in a "normal" installation. I figure a hard drive install will cut the boot time by about 2/3.

At two minutes, the desktop appeared as in the picture above. Fedora auto-detected my broadband connection, and Internet connectivity was easy and fast to set up. On checking the drop-down menu boxes, several things became apparent:

1) NO office productivity suite. Not surprising, as even as far back as Fedora Core 10, there was no office suite. I wonder if this has anything to do with the recent acquisition of Sun Microsystems and Open Office by Oracle. What WAS surprising to me was AbiWord wasn't even included. F.C.-10 at least included AbiWord.

2) NO GIMP - the GNU Image Manipulation Program. Not a huge problem, but past releases of Fedora had it and Ubuntu had it as of 10.04.

3) Firefox 3.6.10 - the most recent release - was included.

4) NO gcc, nmap, wireshark, or much else. What you are getting in the 'live' CD distro is a bare-bones system that will allow you to get online to download all the stuff you need for a decent system. As I found with Ubuntu 10, Ubuntu doesn't give you what they used to on the 'live' CD either. Would be interesting to try out a current Knoppix distro.

Subjective Impressions:

Once fully booted up, performance seemed average compared to my current Fedora hard drive installation. Online browsing with Firefox worked well with no apparent glitches. A browser window can be seen in the picture here.

Older, slower PIII system test:

Next, I tried the CD in my 800 MHz PIII 'coppermine' machine with 1 GB of RAM. This system normally runs acceptably well with an old Ubuntu 8.10 installation, but would NOT win any speed awards.

The first attempt at booting hung at two minutes into the game. I rebooted the machine and after four minutes got the desktop. While the mouse cursor moved about the desktop OK, the response when selecting menu items was extremely sluggish - to the point of being unusable.

This may NOT have been a fair test. I suspect it is developing some hardware issues; it does occasionally hang when booting Ubuntu 8.10. This was NOT a problem back in early 2009 when I first configured that system with Ubuntu 8.10, but it is increasingly so now. Another item I noticed is there were several error messages seen early during both boot attempts.

I don't have another working PIII system to test with, but I suspect FC-14 would work OK on this platform given more RAM (2 GB or more) and reliably functioning hardware.

At two minutes, the desktop appeared as in the picture above. Fedora auto-detected my broadband connection, and Internet connectivity was easy and fast to set up. On checking the drop-down menu boxes, several things became apparent:

1) NO office productivity suite. Not surprising, as even as far back as Fedora Core 10, there was no office suite. I wonder if this has anything to do with the recent acquisition of Sun Microsystems and Open Office by Oracle. What WAS surprising to me was AbiWord wasn't even included. F.C.-10 at least included AbiWord.

2) NO GIMP - the GNU Image Manipulation Program. Not a huge problem, but past releases of Fedora had it and Ubuntu had it as of 10.04.

3) Firefox 3.6.10 - the most recent release - was included.

4) NO gcc, nmap, wireshark, or much else. What you are getting in the 'live' CD distro is a bare-bones system that will allow you to get online to download all the stuff you need for a decent system. As I found with Ubuntu 10, Ubuntu doesn't give you what they used to on the 'live' CD either. Would be interesting to try out a current Knoppix distro.

Subjective Impressions:

Once fully booted up, performance seemed average compared to my current Fedora hard drive installation. Online browsing with Firefox worked well with no apparent glitches. A browser window can be seen in the picture here.

Older, slower PIII system test:

Next, I tried the CD in my 800 MHz PIII 'coppermine' machine with 1 GB of RAM. This system normally runs acceptably well with an old Ubuntu 8.10 installation, but would NOT win any speed awards.

The first attempt at booting hung at two minutes into the game. I rebooted the machine and after four minutes got the desktop. While the mouse cursor moved about the desktop OK, the response when selecting menu items was extremely sluggish - to the point of being unusable.

This may NOT have been a fair test. I suspect it is developing some hardware issues; it does occasionally hang when booting Ubuntu 8.10. This was NOT a problem back in early 2009 when I first configured that system with Ubuntu 8.10, but it is increasingly so now. Another item I noticed is there were several error messages seen early during both boot attempts.

I don't have another working PIII system to test with, but I suspect FC-14 would work OK on this platform given more RAM (2 GB or more) and reliably functioning hardware.

Wednesday, November 10, 2010

Fedora Core 14 LINUX

I recently downloaded the latest Fedora LINUX "live" CD release - Fedora Core 14. Hopefully within the next week or so I'll be able to actually test it. When that happens, I'll post the results and a couple screenshots here. Meanwhile I've been tied up with doing pre-winter maintenance on my truck, along with handling some other urgent personal matters.

Here is the link to the release notes for Fedora 14:

http://docs.fedoraproject.org/en-US/Fedora/14/html/Release_Notes/index.html

Get your very own copy of Fedora 14 here:

http://fedoraproject.org/en/get-fedora

If you want to try the desktop upgrade feature, you will need the "PreUpgrade" application. Go to http://fedoraproject.org/wiki/Upgradingfor more info.

In other news ...

I also plan to download and test out the new release of Ubuntu. Ubuntu has apparently switched from the traditional GNOME desktop to a new one. It will be interesting to see how that works.

Here is the link to the release notes for Fedora 14:

http://docs.fedoraproject.org/en-US/Fedora/14/html/Release_Notes/index.html

Get your very own copy of Fedora 14 here:

http://fedoraproject.org/en/get-fedora

If you want to try the desktop upgrade feature, you will need the "PreUpgrade" application. Go to http://fedoraproject.org/wiki/Upgradingfor more info.

In other news ...

I also plan to download and test out the new release of Ubuntu. Ubuntu has apparently switched from the traditional GNOME desktop to a new one. It will be interesting to see how that works.

It Snapped Clean Away - Replacing the Front Shocks On My Truck

Yesterday I decided to install new front shock absorbers on my rather elderly Ford truck. I've had the parts for a couple months, but decided I'd better get to it before Winter sets in.

Knowing the parts would be rusted, I sprayed them with WD-40 several times in the past week or two. This, in hopes some would penetrate and help the retaining nuts come loose when I removed them.

I started work on the passenger side. The nut on the top stud of the old shock was jammed on and wouldn't budge. Thinking I'd come back to it in a few minutes, I started work on the bottom stud. Within a minute or two,the bottom mounting nut came off all right - with the threaded end of the stud still stuck in it!! The rest of the stud was still attached to the truck and was holding the shock. [See above photo - bottom portion]I knew I was in trouble then - as the stud was a permanently attached part of the lower suspension arm. With the threaded portion broken off, there was no way to retain the bottom end of the new shock. After some proverbial head scratching, I went back in the house and got online to see how other folks handle this sort of problem. I quickly found out I was NOT alone - this problem is quite common. AND there is a reasonably inexpensive fix.

Fortunately, auto parts stores sell generic "Help" kits to replace broken shock mounting studs. Check places such as Autozone, NAPA, ... The new stud in the repair kit consists of a double-ended stud: the shock absorber mounts to the long, mostly smooth end; the short, slightly fatter threaded end goes into a hole in the frame or suspension member and mounts with a washer and nut. The old stud, of course, must be removed before the new one can be installed. Below I'll detail, in words and pictures, what I did.

Items needed:

New shock mounting stud repair kit - probably should get one for BOTH sides of the vehicle

hand-held "angle grinder" - preferably a 4.5" one. The wheel on a larger 5 or 6" one is too big and will be hitting stuff you don't want cut.

"Cut off" wheel and coarse grinding wheel for the grinder

an electric drill - preferably a 1/2" one

a set of drill bits - preferably titanium coated

A drill bit the right size for the new mounting stud in the repair kit you bought

Center punch and hammer

Here, in a nutshell, is what to do:

1) Use the angle grinder with "cut-off" wheel to remove the broken stud, cutting it off flush with the suspension or frame member it's attached to.

2) If necessary, use the angle grinder to cut through the top mounting stud on the shock absorber itself. That top stud is usually made of fairly mild steel, so one can cut partially through it and snap it off by pulling outward on the bottom end of the shock absorber. You may need to rock it back and forth a couple times, but it will break off with some effort. This is what I did, because the radius of the grinding wheel would have cut into stuff I didn't want damaged if I had gone clear through the stud. You will be working in tight quarters, so BE EXTREMELY CAREFUL to NOT cut the vehicle's coil spring or any other parts when using the grinder.

3) Use a center punch to mark dead center where the stud was.

4) Drill a hole where you made the punch mark. Start with a 1/8" drill and work up through your drill sizes to - in my case, a 1/2" hole - to accommodate the mounting stud. When drilling, coat the drill bit liberally with motor oil to help it cut.

5) On my vehicle, there was a 1/4" raised "shoulder" that was part of the old mounting stud - and was still on the lower suspension arm. I had to thin this down by 1/8" with the coarse wheel in the angle grinder so I could get the back mounting nut and washer fully threaded onto the new stud. Below is the picture of the hole drilled out and the shoulder ground down.

[Yes, I got the hole off center. Didn't start out that way, but I think the large drill bit "crept" out of the small pilot hole - I had to skip several drill sizes between my largest pilot drill and the final hole size. I also was drilling with a long bit at a really bad angle. At least there's enough shoulder metal remaining it shouldn't hurt anything. The rubber bushing on the new shock still has plenty of shoulder to bear against, so a washer wasn't necessary.]

6) Once the new stud is able to be nutted in place, you are ready to install the new shock. Below is the picture of the new shock installed.

Notes:

I got BOTH the shocks replaced within an hour and a half. The driver's side lower mounting stud did NOT break when I removed the nut, so all I had to do there is cut the top mounting stud on the shock and remove it as described in step 2 above.

Frankly, I expected the worst, given what immediately happened when I started the job. Thus I bought TWO repair kits so if the other one broke I'd have the parts right there.

My local auto supply store only had one lower shock mount repair kit in stock, but they were able to locate one in a neighboring area and get it held for me so I could drive over and get it.

I'm keeping my extra repair kit around in case I need it in the future.

I am eternally grateful to my neighbor for the use of his 4.5" angle grinder and 1/2" electric hand drill, as well as to several good folks on the Internet whose posts helped me deal with the problem at hand.

Sunday, October 31, 2010

Configuring Routers in SOHO Environments

Last week, I set up a LAN (local area network) at my house so I could share my Internet connection with other family members. Since my broadband modem only had provision for one device, I would need either a different broadband modem, or a router, to accommodate more than one work station. I checked with my ISP and was not terribly surprised when even THEY could not give me any information as to how best to set this up. They indicated they would allow up to four PCs to share the connection without incurring any additional charges. They were quite intent on "upgrading" me to their own wireless modem - for an additional $100 to purchase. I wasn't sure I even needed or wanted wireless, and in any event could buy newer equipment cheaper elsewhere. Instead I went out and purchased my own router, which can accommodate up to several computers or other network enabled devices.

In Brief - Why I have Written This Piece

A computer is NOT like a washing machine that you simply connect to utilities, use when you want it, and then forget it. But many folks unwittingly treat their PC that way - and that's how they get into trouble with lost data, 'catch' computer viruses, become victims of online ID theft, etc. Most folks I've met who have broadband modems or routers do not even have the internal firewall turned on, let alone properly set up. Many home and small business wireless networks are NOT secured properly; they're functioning as wireless public "hotspots" that anyone can connect to for whatever purpose - legal or otherwise. There are criminals who drive through neighborhoods with Wi-fi enabled laptop computers LOOKING for such unguarded networks through which to commit all manner of cyber crimes. I hope that anyone reading this who isn't already familiar with how to secure their home/small office networks can use this information to help improve their online security.

What a Router Does:

A router is used to connect two or more computer networks. When a router receives a data packet, it looks at the header information on that packet to see where it came from, and to what computer it is addressed to. The router checks to see if the packet is addressed to another computer on the same network where it originated, or if it needs to be transferred to another network. After determining where data packets it receives are coming from and addressed to, the router sends them where they need to go. In Small Office/Home Office (SOHO) environments, routers are often used so that several computers or even network enabled appliances such as TVs and game consoles can all share one internet connection. Some cable and DSL modems already have built-in routers and multiple Ethernet ports, while others (like mine) only have one connection.

Routers may either be "wired" or, "wireless" to provide 802.11 b,g or n Wi-fi access. Most "wireless" routers I've seen and dealt with also have provision for up to four RJ-45 Ethernet ports for connecting to wired computers.

Here are some GENERAL guidelines for choosing and setting up a router for SOHO use, based on my own research and on-the-job experience. This is NOT intended to be an exhaustive work; it is strictly intended to show some basic considerations for SOHO router setup. "Your mileage may vary" depending on your ISP, equipment, and particular needs:

1) Do you need Wi-fi (wireless) capability for laptops or other portable devices? If not, you might want to stay with a strictly WIRED Ethernet router. While many folks have adopted Wi-fi and love it, it is generally considered LESS safe or secure than wired. There is always the chance that criminals can hack into your router via your Wi-fi signal to access your Internet connection or networked PCs for nefarious purposes. If you MUST have Wi-fi, make sure your router/access point supports the newer and somewhat more secure WAP/WAP2 encryption protocols.

2) Firewall A built-in "hardware" firewall is mandatory. Whether buying a wired or wi-fi router, get one with a built-in firewall. Hardware firewalls placed between the Internet and your network perform a vital function by preventing certain types of cyber attacks from ever reaching your network in the first place. By contrast, "software" firewalls such as Zone Alarm, Windows Firewall, or the ones that come with the LINUX operating system, are installed on individual work stations and are a last line of resistance for them AFTER the network itself has been breached.

3) Configuration All routers, whether wired or wireless, that I have used have a 'configuration' web page that one logs into in order to set the thing up. Some have Windows software, a sort of "configuration wizard" on a CD, supplied with the device. I generally avoid using these, preferring to use the configuration web page instead. Once your PC is connected to the router, you can access the configuration web page by opening your web browser and pointing it to whatever local IP address your router's manual tells you. Generally it will be http://192.168.1.1, or sometimes http://192.168.1.100. You will be prompted for a username and password. The word "admin" or "administrator" is often the DEFAULT for BOTH the username and password. Again, check your manual for the exact login procedure.

Plug the router in, connect it to your PC - preferably with an Ethernet cable, and turn it on. Do NOT connect it to your DSL/broadband modem YET. Log in as described above, in keeping with the directions that came with your unit.

Once logged in, IMMEDIATELY do the following:

a) Change the default administrator username and passwords to something that others cannot easily guess. Especially for passwords, stay away from names of family members or pets, anniversary or birth dates, ... Also stay away from words that would appear in ANY language dictionary. A random string of letters and numbers is best; for something easier for you to remember you could also think of a sentence and pick the first or last letters of each word, then mix in some numbers. THAT is quite likely a good, strong password.

FAILURE to take this simple step may result in criminals easily getting in and reconfiguring your router, using your Internet connection for criminal activities - especially on wi-fi enabled routers, and/or attacking/hacking computers on your local network!!

b) AVOID taking the lazy way out by having Windows, or your web browser (in Windows or LINUX), remember the password! If your PC is ever compromised, that information may end up in the hands of bad people. Also, if you don't use the password you will forget it. Then it will be lost when your PC needs the inevitable reformat and re-install of its operating system. All you can do then is do a "hard reset" on the router to factory settings and reconfigure it from scratch. See your manual for how to do this.

c) Routers - often have a "network name" or, in the case of Wi-fi, a SSID (Service Set Identifier). Whichever default is there, whether it be "Belkin" or "Linksys", or whatever, should immediately be changed to something unrelated. Why make it any easier for the bad guys by TELLING THEM what brand of equipment you have? That just gives them an edge when probing your network for vulnerabilities. Also, avoid using your personal, family name, or business name for your network name or SSID as well - that identifies it as yours if someone wants to specifically mess with you. [This is NOT the 1950s any more, and growing numbers of people are having these sorts of problems nowadays.] For Wi-fi, the SSID should NEVER be broadcast unless you are setting up a public "hotspot". So make sure to select "Do not broadcast the SSID" in your wireless configuration menu. Anybody who is not authorized to connect to your network most surely does NOT need to know the SSID!

d) DHCP v.s. Static IP addresses - There are exceptions to this, but most home Internet connections use DHCP (Dynamic Host Configuration Protocol) for assigning you an IP address "on the fly". Most routers are by default set up to use DHCP to connect to the broadband modem. On your LAN (local area network), if you need to share files and/or printers, you will need LOCAL static IP addresses - usually in the 192.168.x.x range - for each of your PCs or networked printers. There are lots of good tutorials online for doing this. On the other hand, if you simply want a couple PCs to both have Internet access but NOT share files or printers, you could simply set them to use DHCP as well IF your router provides its own internal DHCP server for the LAN. Check your router's instruction manual/specs for more details.

e) Encrypted v.s. non-encrypted configuration access - If your router offers it, set the configuration page for "encrypted access"; it's MUCH safer! So, instead of pointing your browser to, say, http://192.168.1.1 to access the configuration page, you would now use https://192.168.1.1 as the IP for logging in. The https shows it's encrypted; the padlock symbol should display on your browser window when logged in this way.

f) Configuration login from outside - if you don't envision needing to log in to the router's configuration page from outside your local network, such as from a computer away from home, leave this DISABLED. This is yet another step in securing your network from unauthorized external access or changes.

g) Wi-fi access to configuration page - if your wi-fi router has provisions for this and one of your PCs is connected by wired Ethernet, DISABLE wireless access to the configuration page. This prevents someone from sitting in their car down the street and wirelessly hacking away at your router configuration page.

h) Wi-fi encryption - use the stronger WAP or "WAP2 Personal", rather than the weaker WEP encryption standard, on your wi-fi networked devices. "WAP/WAP2 Enterprise" is a whole different animal that requires an authentication server and is much more difficult to set up. Most SOHO networks don't currently use it.

i) MAC address filtering - every networked device, whether wired or wireless, has a unique hardware identifier called a MAC (Media Access Control) address. If your router offers MAC address filtering, use it. This further helps out by discriminating AGAINST any computer NOT listed in the router's MAC address lookup table. This also allows you to selectively shut off your kid's Internet access if he/she is misbehaving online. As an aside, you can find your computer's MAC address by opening a command prompt and typing "ipconfig" on a Windows box or "ifconfig" on a LINUX system. On my LINUX box, it is displayed by the ifconfig command in this format: "HWaddr 89:8A:2F:ED:5A:2G" . On any system, it will be a string of 6 pairs of hexadecimal numbers separated by colons - as in the above mentioned example. See your router's manual for how to set up MAC address filtering on your particular equipment.

j) On the firewall configuration, make sure the firewall is set to drop PING requests. Block any unused/unneeded ports if your router's firewall settings menu allows it. Port 80 needs to be open for basic Internet access, but often computers have other ports open by default that don't necessarily need to be. If you're strictly using web based email such as a "yahoo" account or Google's "gmail" through your browser, for example, as opposed to a POP3 server with MS Outlook, you can block the common ports used for POP3 email services. SMPT ports 25 and 110, for example. Many hardware firewalls allow blocking of access to certain sites or domains - good to know if you don't want your kids using Facebook, for example.

k) Wireless "peer to peer" or file sharing - DISABLE this if you don't really need it. Again, if you simply need a couple systems to access the Internet, but NOT share files or printers, this setting is safer. Obviously, if you DO need to share files and/or printers, then leave this ENABLED.

l) WAP Passphrase - make up a passphrase just as you did in step "a" above, though USE A DIFFERENT ONE. The WAP passphrase provides the basis for the encryption algorithm to work - and must be the same on BOTH the Wi-fi router and ANY client PC for them to work together. Again, use something that is not readily guessable or subject to a "dictionary attack".

Now, Test It Out

After you have done all this, go ahead and connect the router to the DSL/broadband modem. First test out any WIRED PC connections and make sure they can connect to the Internet. Correct any problems with the wired connections BEFORE dealing with the Wi-fi (if you have that). By doing things in this order, you have verified that your broadband/DSL connectivity and router are working BEFORE introducing any complications caused by Wi-fi issues.

Now, go back and configure any Wi-fi enabled PCs or laptops per any supplied instructions, using the same SSID settings, WAP encryption passphrases, ... as you did on the router. On many Windows PCs, you will need to reboot for the settings to take effect. Hopefully, if everything was configured properly, you will have Internet access on all your networked machines. If you ARE sharing files or printers, you will also need to configure those functions in the customary way for your equipment/operating system(s).

One caveat - bear in mind that many older wireless devices do NOT support WAP/WAP2 protocol. If you have an older PC or laptop with an older Wi-fi interface that cannot use WAP, you might want to consider buying a USB Wi-fi "dongle" that DOES support the newer protocol.

That's about all for now. While this is by far NOT a comprehensive tutorial on network security, it hopefully will help interested parties to avoid the most common mistakes.

In Brief - Why I have Written This Piece

A computer is NOT like a washing machine that you simply connect to utilities, use when you want it, and then forget it. But many folks unwittingly treat their PC that way - and that's how they get into trouble with lost data, 'catch' computer viruses, become victims of online ID theft, etc. Most folks I've met who have broadband modems or routers do not even have the internal firewall turned on, let alone properly set up. Many home and small business wireless networks are NOT secured properly; they're functioning as wireless public "hotspots" that anyone can connect to for whatever purpose - legal or otherwise. There are criminals who drive through neighborhoods with Wi-fi enabled laptop computers LOOKING for such unguarded networks through which to commit all manner of cyber crimes. I hope that anyone reading this who isn't already familiar with how to secure their home/small office networks can use this information to help improve their online security.

What a Router Does:

A router is used to connect two or more computer networks. When a router receives a data packet, it looks at the header information on that packet to see where it came from, and to what computer it is addressed to. The router checks to see if the packet is addressed to another computer on the same network where it originated, or if it needs to be transferred to another network. After determining where data packets it receives are coming from and addressed to, the router sends them where they need to go. In Small Office/Home Office (SOHO) environments, routers are often used so that several computers or even network enabled appliances such as TVs and game consoles can all share one internet connection. Some cable and DSL modems already have built-in routers and multiple Ethernet ports, while others (like mine) only have one connection.

Routers may either be "wired" or, "wireless" to provide 802.11 b,g or n Wi-fi access. Most "wireless" routers I've seen and dealt with also have provision for up to four RJ-45 Ethernet ports for connecting to wired computers.

Here are some GENERAL guidelines for choosing and setting up a router for SOHO use, based on my own research and on-the-job experience. This is NOT intended to be an exhaustive work; it is strictly intended to show some basic considerations for SOHO router setup. "Your mileage may vary" depending on your ISP, equipment, and particular needs:

1) Do you need Wi-fi (wireless) capability for laptops or other portable devices? If not, you might want to stay with a strictly WIRED Ethernet router. While many folks have adopted Wi-fi and love it, it is generally considered LESS safe or secure than wired. There is always the chance that criminals can hack into your router via your Wi-fi signal to access your Internet connection or networked PCs for nefarious purposes. If you MUST have Wi-fi, make sure your router/access point supports the newer and somewhat more secure WAP/WAP2 encryption protocols.

2) Firewall A built-in "hardware" firewall is mandatory. Whether buying a wired or wi-fi router, get one with a built-in firewall. Hardware firewalls placed between the Internet and your network perform a vital function by preventing certain types of cyber attacks from ever reaching your network in the first place. By contrast, "software" firewalls such as Zone Alarm, Windows Firewall, or the ones that come with the LINUX operating system, are installed on individual work stations and are a last line of resistance for them AFTER the network itself has been breached.

3) Configuration All routers, whether wired or wireless, that I have used have a 'configuration' web page that one logs into in order to set the thing up. Some have Windows software, a sort of "configuration wizard" on a CD, supplied with the device. I generally avoid using these, preferring to use the configuration web page instead. Once your PC is connected to the router, you can access the configuration web page by opening your web browser and pointing it to whatever local IP address your router's manual tells you. Generally it will be http://192.168.1.1, or sometimes http://192.168.1.100. You will be prompted for a username and password. The word "admin" or "administrator" is often the DEFAULT for BOTH the username and password. Again, check your manual for the exact login procedure.

Plug the router in, connect it to your PC - preferably with an Ethernet cable, and turn it on. Do NOT connect it to your DSL/broadband modem YET. Log in as described above, in keeping with the directions that came with your unit.

Once logged in, IMMEDIATELY do the following:

a) Change the default administrator username and passwords to something that others cannot easily guess. Especially for passwords, stay away from names of family members or pets, anniversary or birth dates, ... Also stay away from words that would appear in ANY language dictionary. A random string of letters and numbers is best; for something easier for you to remember you could also think of a sentence and pick the first or last letters of each word, then mix in some numbers. THAT is quite likely a good, strong password.

FAILURE to take this simple step may result in criminals easily getting in and reconfiguring your router, using your Internet connection for criminal activities - especially on wi-fi enabled routers, and/or attacking/hacking computers on your local network!!

b) AVOID taking the lazy way out by having Windows, or your web browser (in Windows or LINUX), remember the password! If your PC is ever compromised, that information may end up in the hands of bad people. Also, if you don't use the password you will forget it. Then it will be lost when your PC needs the inevitable reformat and re-install of its operating system. All you can do then is do a "hard reset" on the router to factory settings and reconfigure it from scratch. See your manual for how to do this.

c) Routers - often have a "network name" or, in the case of Wi-fi, a SSID (Service Set Identifier). Whichever default is there, whether it be "Belkin" or "Linksys", or whatever, should immediately be changed to something unrelated. Why make it any easier for the bad guys by TELLING THEM what brand of equipment you have? That just gives them an edge when probing your network for vulnerabilities. Also, avoid using your personal, family name, or business name for your network name or SSID as well - that identifies it as yours if someone wants to specifically mess with you. [This is NOT the 1950s any more, and growing numbers of people are having these sorts of problems nowadays.] For Wi-fi, the SSID should NEVER be broadcast unless you are setting up a public "hotspot". So make sure to select "Do not broadcast the SSID" in your wireless configuration menu. Anybody who is not authorized to connect to your network most surely does NOT need to know the SSID!

d) DHCP v.s. Static IP addresses - There are exceptions to this, but most home Internet connections use DHCP (Dynamic Host Configuration Protocol) for assigning you an IP address "on the fly". Most routers are by default set up to use DHCP to connect to the broadband modem. On your LAN (local area network), if you need to share files and/or printers, you will need LOCAL static IP addresses - usually in the 192.168.x.x range - for each of your PCs or networked printers. There are lots of good tutorials online for doing this. On the other hand, if you simply want a couple PCs to both have Internet access but NOT share files or printers, you could simply set them to use DHCP as well IF your router provides its own internal DHCP server for the LAN. Check your router's instruction manual/specs for more details.

e) Encrypted v.s. non-encrypted configuration access - If your router offers it, set the configuration page for "encrypted access"; it's MUCH safer! So, instead of pointing your browser to, say, http://192.168.1.1 to access the configuration page, you would now use https://192.168.1.1 as the IP for logging in. The https shows it's encrypted; the padlock symbol should display on your browser window when logged in this way.

f) Configuration login from outside - if you don't envision needing to log in to the router's configuration page from outside your local network, such as from a computer away from home, leave this DISABLED. This is yet another step in securing your network from unauthorized external access or changes.

g) Wi-fi access to configuration page - if your wi-fi router has provisions for this and one of your PCs is connected by wired Ethernet, DISABLE wireless access to the configuration page. This prevents someone from sitting in their car down the street and wirelessly hacking away at your router configuration page.

h) Wi-fi encryption - use the stronger WAP or "WAP2 Personal", rather than the weaker WEP encryption standard, on your wi-fi networked devices. "WAP/WAP2 Enterprise" is a whole different animal that requires an authentication server and is much more difficult to set up. Most SOHO networks don't currently use it.

i) MAC address filtering - every networked device, whether wired or wireless, has a unique hardware identifier called a MAC (Media Access Control) address. If your router offers MAC address filtering, use it. This further helps out by discriminating AGAINST any computer NOT listed in the router's MAC address lookup table. This also allows you to selectively shut off your kid's Internet access if he/she is misbehaving online. As an aside, you can find your computer's MAC address by opening a command prompt and typing "ipconfig" on a Windows box or "ifconfig" on a LINUX system. On my LINUX box, it is displayed by the ifconfig command in this format: "HWaddr 89:8A:2F:ED:5A:2G" . On any system, it will be a string of 6 pairs of hexadecimal numbers separated by colons - as in the above mentioned example. See your router's manual for how to set up MAC address filtering on your particular equipment.

j) On the firewall configuration, make sure the firewall is set to drop PING requests. Block any unused/unneeded ports if your router's firewall settings menu allows it. Port 80 needs to be open for basic Internet access, but often computers have other ports open by default that don't necessarily need to be. If you're strictly using web based email such as a "yahoo" account or Google's "gmail" through your browser, for example, as opposed to a POP3 server with MS Outlook, you can block the common ports used for POP3 email services. SMPT ports 25 and 110, for example. Many hardware firewalls allow blocking of access to certain sites or domains - good to know if you don't want your kids using Facebook, for example.

k) Wireless "peer to peer" or file sharing - DISABLE this if you don't really need it. Again, if you simply need a couple systems to access the Internet, but NOT share files or printers, this setting is safer. Obviously, if you DO need to share files and/or printers, then leave this ENABLED.

l) WAP Passphrase - make up a passphrase just as you did in step "a" above, though USE A DIFFERENT ONE. The WAP passphrase provides the basis for the encryption algorithm to work - and must be the same on BOTH the Wi-fi router and ANY client PC for them to work together. Again, use something that is not readily guessable or subject to a "dictionary attack".

Now, Test It Out

After you have done all this, go ahead and connect the router to the DSL/broadband modem. First test out any WIRED PC connections and make sure they can connect to the Internet. Correct any problems with the wired connections BEFORE dealing with the Wi-fi (if you have that). By doing things in this order, you have verified that your broadband/DSL connectivity and router are working BEFORE introducing any complications caused by Wi-fi issues.

Now, go back and configure any Wi-fi enabled PCs or laptops per any supplied instructions, using the same SSID settings, WAP encryption passphrases, ... as you did on the router. On many Windows PCs, you will need to reboot for the settings to take effect. Hopefully, if everything was configured properly, you will have Internet access on all your networked machines. If you ARE sharing files or printers, you will also need to configure those functions in the customary way for your equipment/operating system(s).

One caveat - bear in mind that many older wireless devices do NOT support WAP/WAP2 protocol. If you have an older PC or laptop with an older Wi-fi interface that cannot use WAP, you might want to consider buying a USB Wi-fi "dongle" that DOES support the newer protocol.

That's about all for now. While this is by far NOT a comprehensive tutorial on network security, it hopefully will help interested parties to avoid the most common mistakes.

Tuesday, October 19, 2010

What's Old Is New Again - Pre 1984 Telco Phones

Yes, it's been a while since I posted an entry here. Several work and family related issues have kept me quite busy.

Some of my interests may seem a bit anachronistic, especially when included on the same blog site with high tech solid state electronics and modern desktop PCs. Here is one example:

The Venerable "Plain ol' Telephone"

This past week, I bought a Western Electric model 2500 desk phone off eBay. It was built in 1980, according to the date code sticker on the bottom. This is the 'standard' touch tone desk phone common in America from the late 1960s through the 1980s. While I mainly got this because of nostalgia, the old telco provided phones also offer the following advantages:

1) More rugged construction - the telco supplied phones were generally quite robust and could take an amazing amount of abuse.

2) Often, the sound quality of the old phones is better than that of the newer models.

3) Fairly easy to service - Prior to the breakup of the Bell System in the early 1980s, customers generally rented their instruments from the phone company. Telephone company employees serviced these instruments in people's homes and businesses, thus these phones were made for fast, easy service and repair.

4) These are often quite a conversation piece, as there is a whole generation coming of age that has never used them!

When I got my phone in the mail today, I eagerly plugged it in and tried it out. The handset had that good, substantial heft I remembered from the past. The sound quality is good. But the touch tone pad did NOT work. Since the seller had a 100% rating and assured in the ad that it was "100% functional", I figured something might have happened during shipping. After all, this IS a 30-year old piece of equipment. After doing some research online, downloading some schematics, and verifying all the wiring was good using a DVM, I found out that many of the older touch tone pads are polarity sensitive. In other words, some phones will work if the line polarity is reversed, but many won't. My phone, with the 35-series dial, is one of the models that will NOT work if the phone line polarity is reversed. I simply reversed the incoming line connections and voila - it now works! I have posted several links I found useful in troubleshooting my old phone, as well as a couple sites that sell vintage repair parts and even show how you can safely use Grandma's "candlestick" style phone on today's telco systems!

Some Useful Resources For Those Interested In Plain Ol' Phones:

Parts and Repairs for Telephones

http://www.telephonetribute.com/parts_sources.htm

Phone Circuits and Stuff - even has some circuits for making your own 'hold' button, audio interfaces for amplifying/recording off the phone line, using old phones as intercoms, ... VERY useful stuff here!

http://www.epanorama.net/links/telephone.html#phonecircuits

Western Electric Touch Tone

http://www.porticus.org/bell/telephones-technical_dials-touchtone.html

Western Electric 500 Series Phones

http://www.paul-f.com/we500typ.htm#Model

Technical Documentation for Bell System Phones

http://www.paul-f.com/BSP.html

Believe it or not, you CAN still use ANY of those old rotary dial phones - even on those horrible voice menu systems that say "Press 1 for English", ... See the links below:

Old Phones, Parts, "Pulse-to-tone converters" - VERY cool site; lots of useful restoration parts and stuff! Probably will be shopping there soon.

http://www.oldphoneworks.com

Wiring a Touch Tone Pad to Any Antique Phone

http://atcaonline.com/ttpad.html

Some of my interests may seem a bit anachronistic, especially when included on the same blog site with high tech solid state electronics and modern desktop PCs. Here is one example:

The Venerable "Plain ol' Telephone"

This past week, I bought a Western Electric model 2500 desk phone off eBay. It was built in 1980, according to the date code sticker on the bottom. This is the 'standard' touch tone desk phone common in America from the late 1960s through the 1980s. While I mainly got this because of nostalgia, the old telco provided phones also offer the following advantages:

1) More rugged construction - the telco supplied phones were generally quite robust and could take an amazing amount of abuse.

2) Often, the sound quality of the old phones is better than that of the newer models.

3) Fairly easy to service - Prior to the breakup of the Bell System in the early 1980s, customers generally rented their instruments from the phone company. Telephone company employees serviced these instruments in people's homes and businesses, thus these phones were made for fast, easy service and repair.

4) These are often quite a conversation piece, as there is a whole generation coming of age that has never used them!

When I got my phone in the mail today, I eagerly plugged it in and tried it out. The handset had that good, substantial heft I remembered from the past. The sound quality is good. But the touch tone pad did NOT work. Since the seller had a 100% rating and assured in the ad that it was "100% functional", I figured something might have happened during shipping. After all, this IS a 30-year old piece of equipment. After doing some research online, downloading some schematics, and verifying all the wiring was good using a DVM, I found out that many of the older touch tone pads are polarity sensitive. In other words, some phones will work if the line polarity is reversed, but many won't. My phone, with the 35-series dial, is one of the models that will NOT work if the phone line polarity is reversed. I simply reversed the incoming line connections and voila - it now works! I have posted several links I found useful in troubleshooting my old phone, as well as a couple sites that sell vintage repair parts and even show how you can safely use Grandma's "candlestick" style phone on today's telco systems!

Some Useful Resources For Those Interested In Plain Ol' Phones:

Parts and Repairs for Telephones

http://www.telephonetribute.com/parts_sources.htm

Phone Circuits and Stuff - even has some circuits for making your own 'hold' button, audio interfaces for amplifying/recording off the phone line, using old phones as intercoms, ... VERY useful stuff here!

http://www.epanorama.net/links/telephone.html#phonecircuits

Western Electric Touch Tone

http://www.porticus.org/bell/telephones-technical_dials-touchtone.html

Western Electric 500 Series Phones

http://www.paul-f.com/we500typ.htm#Model

Technical Documentation for Bell System Phones

http://www.paul-f.com/BSP.html

Believe it or not, you CAN still use ANY of those old rotary dial phones - even on those horrible voice menu systems that say "Press 1 for English", ... See the links below:

Old Phones, Parts, "Pulse-to-tone converters" - VERY cool site; lots of useful restoration parts and stuff! Probably will be shopping there soon.

http://www.oldphoneworks.com

Wiring a Touch Tone Pad to Any Antique Phone

http://atcaonline.com/ttpad.html

Labels:

desk phone,

Model 2500,

Model 500,

telephone,

Western Electric

Tuesday, September 28, 2010

TS1 Test Fixture

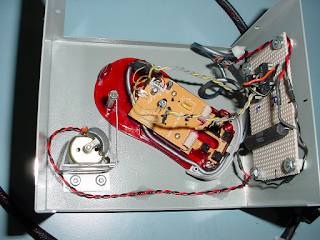

Regular readers of this blog have seen a few of the automated test fixtures I have built.

Another fixture I built a few years ago monitors NEMA TS-1 output signals on up to 8 boards under test. TS-1 outputs are based on an open collector circuit configuration, producing a binary "low" or "high" condition. In simple terms these signals can be thought of as a "contact closure".

This fixture, as seen in the photos, contains a microcontroller and a couple "mux" boards for handling all the signals from two plug-in card cages. The TS1 fixture and card cages were mounted in a standard 19" rack cabinet. Each of the two card cages had a 33-conductor cable which plugs into the fixture - hence the pair of DB-37 female connectors seen in the top photo. These cables each handled 32 TS1 signals plus ground.

This device, as with the serial relay controller and the automated mouse movement emulator described in earlier blog posts, was controlled by a PC running LabVIEW software on Windows XP.

The box is an aluminum LMB enclosure; I used a dremmel tool to make the cut-outs for the DB-37 and DB-9 connectors, and a drill press for the round holes. The two large PCBs were made at an outside "board house", then populated by in-house assemblers. I mounted everything in the LMB enclosure and installed the chassis wiring. The smaller PCB - measuring about 2" x 2" - is the microcontroller board. The smallest PCB, connected to the microcontroller board via a ribbon cable, handles its RS-232 and power supply connections.

I built several of these fixtures for both engineering and manufacturing testing.

Monday, September 13, 2010

Of "Walled Gardens" and Computing Freedom

In an article entitled Intel's Walled Garden Plan to Put A/V Vendors Out of Business, Paul Otellini of Intel explained the reasoning behind its purchase of McAfee Anti Virus. Otellini described Intel's vision of "only allowing trusted and signed code" to run on the Intel x86 platform. The article went on to describe a scenario where you would get your software in a manner similar to the Apple "App Store" used on the iPhone.

Granted, the current security model purveyed by anti virus vendors is very labor intensive, inefficient, and all too often fails to catch a threat before it causes damage out in the world. Intel's model would offer a few advantages and probably eliminate some of the above-mentioned problems. If AV functionality was integral to the system's architecture, it would eliminate the problem of computer illiterate users not taking proper care of their PCs. The end user would not need to worry about installing anti virus software any more. All that said, this whole idea is NOT without significant shortcomings and impacts to system usability.

Users need to consider the following before they unconditionally embrace Intel's vision of a security utopia:

1) Just like on the iPhone, you would not be able to conveniently run software that wasn't approved by Intel/McAfee. Granted that some folks have found hacks to bypass the iPhone controls, but they do so at risk of other issues including violating their phone warranties.

2) Since software developers would have to deal with some "trusted" signing authority to get their code approved to run on Intel x86, this could well cause problems for open source users and developers - as much of this software is created on a low budget and often distributed for free.

3) What about folks writing their own code, scripts, etc.? No code you or I write on our computer would run until/unless it were signed by the "trusted" signing authority. This potentially includes batch files and UNIX/LINUX shell scripts.

4) An outgrowth of point 2 above, folks wanting to run LINUX, BSD, or other open source software could be in real trouble. At the very least, we could be forced into paying major dollars for our software to one or two large vendors who could afford the signing fees.

5) As one reader posted in the comments section, just because your software is "trusted" and signed does NOT mean it is without security holes or that it still couldn't cause trouble by running malicious code buried in a file.

6) Early in my career as a Windows user, I stopped using McAfee because of the severe impact it had on system resources. Several IT industry professionals I've talked to recommend other anti virus software as being more effective than McAfee at detecting viruses. I shudder at the thought of EVER using their products again on any computer I rely upon for critical work.

In Summary:

Clearly, there needs to be a new paradigm for secure computing. Cyber crime and terrorism are both a growing threat in today's world. That said, we need solutions that work for everyone. We need solutions that do not interfere with our freedom to use our machines for whatever LAWFUL purpose we want. We need solutions that allow us to continue running whatever OS or applications we FREELY choose. We do NOT need a "Nanny State" or "Nanny Company" solution to the problem.

Granted, the current security model purveyed by anti virus vendors is very labor intensive, inefficient, and all too often fails to catch a threat before it causes damage out in the world. Intel's model would offer a few advantages and probably eliminate some of the above-mentioned problems. If AV functionality was integral to the system's architecture, it would eliminate the problem of computer illiterate users not taking proper care of their PCs. The end user would not need to worry about installing anti virus software any more. All that said, this whole idea is NOT without significant shortcomings and impacts to system usability.

Users need to consider the following before they unconditionally embrace Intel's vision of a security utopia:

1) Just like on the iPhone, you would not be able to conveniently run software that wasn't approved by Intel/McAfee. Granted that some folks have found hacks to bypass the iPhone controls, but they do so at risk of other issues including violating their phone warranties.

2) Since software developers would have to deal with some "trusted" signing authority to get their code approved to run on Intel x86, this could well cause problems for open source users and developers - as much of this software is created on a low budget and often distributed for free.

3) What about folks writing their own code, scripts, etc.? No code you or I write on our computer would run until/unless it were signed by the "trusted" signing authority. This potentially includes batch files and UNIX/LINUX shell scripts.

4) An outgrowth of point 2 above, folks wanting to run LINUX, BSD, or other open source software could be in real trouble. At the very least, we could be forced into paying major dollars for our software to one or two large vendors who could afford the signing fees.

5) As one reader posted in the comments section, just because your software is "trusted" and signed does NOT mean it is without security holes or that it still couldn't cause trouble by running malicious code buried in a file.

6) Early in my career as a Windows user, I stopped using McAfee because of the severe impact it had on system resources. Several IT industry professionals I've talked to recommend other anti virus software as being more effective than McAfee at detecting viruses. I shudder at the thought of EVER using their products again on any computer I rely upon for critical work.

In Summary:

Clearly, there needs to be a new paradigm for secure computing. Cyber crime and terrorism are both a growing threat in today's world. That said, we need solutions that work for everyone. We need solutions that do not interfere with our freedom to use our machines for whatever LAWFUL purpose we want. We need solutions that allow us to continue running whatever OS or applications we FREELY choose. We do NOT need a "Nanny State" or "Nanny Company" solution to the problem.

Monday, August 23, 2010

HP Printer Support in LINUX

Last week I got around to fixing my printer issues on my Fedora box. As mentioned in a recent post, I had problems getting the HP printing software installed and working. As I also mentioned in a recent post, before trying to install applications or plugins, one should first apply ALL available and relevant system updates. Waiting until later to do this cost me much time and aggravation. There were updates to the CUPS printing software and other parts that were needed for the Laserjet printer or Open Office to install successfully. Once those updates were in place, I was able to quickly install the HP printing software and Open Office and get on with life.

Herein I will detail how I got printing enabled on my LINUX system, including hard-to-find but critical information on getting it to work on Fedora SE LINUX.

For those of us who own HP printers, there is a third party application called "HPLIP". This stands for "HP LINUX Imaging and Printing" and allows support for both printing and scanning. The following link will take you to the page where you may download HPLIP and also verify that your printer is supported:

http://hplipopensource.com/hplip-web/index.html

The download link will take you to another page where you will select your LINUX distribution and version, the printer type and model. Once you do this you will be given the correct version for your setup.

The following link tells you in excellent detail through words and screenshots how to run the HPLIP installer and what you will see on your screen at each step.

http://hplipopensource.com/hplip-web/install/install/index.html

BEFORE Installation:

BEFORE installing HPLIP, make sure your printer is DISCONNECTED from the computer!! The installer will prompt you when to connect the printer.

You need to be connected to the Internet during the entire installation, as your system will likely need to download other stuff to resolve dependencies. You will run the installer from the command line as detailed in the installation instructions.

Ubuntu:

Since the install instructions page shows a Ubuntu installation, things should proceed as in the pictures.

Installing on SE LINUX:

Fedora is quite similar to a Ubuntu installation EXCEPT you FIRST must disable the "SE" or "security enhanced" functionality in order to carry out the installation. [Your system will give you a message on the command line to this effect - this is NOT detailed in the step-by-step procedure shown in the above link]

Do the following:

1) Select the "SYSTEM" menu at the upper left-hand corner of your screen.

2) Select "Administration" ,

3) Choose "SE LINUX Management" from the drop-down menu that appears. You will be prompted for the root, or superuser password.

4) A window entitled "SE LINUX Administration" will appear within a few seconds.

Under "Status", you will see "system Default Enforcing mode", "Current Enforcing mode", and "system Default Policy type". Under "Current Enforcing Mode", select "Permissive".

5) Under "File" menu, select "quit" to log out of "SE LINUX Administration".

Once this is done, follow the instructions at the link above. The installer should do its thing.

Completing the Installation:

You should notice a blue "HP" logo in the upper right-hand portion of your screen.

You MAY be prompted to reboot or log out, then log back in.

If that is the case, you will need to run a "hp-setup" command from the command line to finish the installation. If you are running Fedora, you may need to disable SE functionality again as you did above. At this point, a dialog window will appear. This is the configuration window for setting up your printer. You will see a form to enter the printer name, description, and location [office, lab, ...]. Your system will search for a driver and should automatically download what it needs.

Select the "Print Test Page" button - if all has gone right you should be rewarded with a printout of the HPLIP test page.

IMPORTANT Fedora SE LINUX settings for Printing

After installing HPLIP, you should go back into the "SE LINUX Administration" menu and reset the "Current Enforcing Mode" to "Enforcing". Failure to do this will leave your system vulnerable to attacks!

In order to keep SE LINUX's "Current Enforcing Mode" set to "Enforcing" and STILL BE ABLE TO PRINT, do the following:

1) In the "SE LINUX Administration" menu, select "Process Domain"

2) Find "cupsd", cupsd_lpd", and "cups_pdf" - mark those "permissive" by clicking on each one and selecting the yellow "permissive" triangle symbol right above the list.

3) Click on the "file" menu, slect "close" so that the settings are saved and you are logged out of the "SE LINUX Management" menu.

4) Open a text file on your system and try printing it - it should print now even with "Current Enforcing Mode" set to "Enforcing".

Herein I will detail how I got printing enabled on my LINUX system, including hard-to-find but critical information on getting it to work on Fedora SE LINUX.

For those of us who own HP printers, there is a third party application called "HPLIP". This stands for "HP LINUX Imaging and Printing" and allows support for both printing and scanning. The following link will take you to the page where you may download HPLIP and also verify that your printer is supported:

http://hplipopensource.com/hplip-web/index.html

The download link will take you to another page where you will select your LINUX distribution and version, the printer type and model. Once you do this you will be given the correct version for your setup.

The following link tells you in excellent detail through words and screenshots how to run the HPLIP installer and what you will see on your screen at each step.

http://hplipopensource.com/hplip-web/install/install/index.html

BEFORE Installation:

BEFORE installing HPLIP, make sure your printer is DISCONNECTED from the computer!! The installer will prompt you when to connect the printer.

You need to be connected to the Internet during the entire installation, as your system will likely need to download other stuff to resolve dependencies. You will run the installer from the command line as detailed in the installation instructions.

Ubuntu:

Since the install instructions page shows a Ubuntu installation, things should proceed as in the pictures.

Installing on SE LINUX:

Fedora is quite similar to a Ubuntu installation EXCEPT you FIRST must disable the "SE" or "security enhanced" functionality in order to carry out the installation. [Your system will give you a message on the command line to this effect - this is NOT detailed in the step-by-step procedure shown in the above link]

Do the following:

1) Select the "SYSTEM" menu at the upper left-hand corner of your screen.

2) Select "Administration" ,

3) Choose "SE LINUX Management" from the drop-down menu that appears. You will be prompted for the root, or superuser password.

4) A window entitled "SE LINUX Administration" will appear within a few seconds.

Under "Status", you will see "system Default Enforcing mode", "Current Enforcing mode", and "system Default Policy type". Under "Current Enforcing Mode", select "Permissive".

5) Under "File" menu, select "quit" to log out of "SE LINUX Administration".

Once this is done, follow the instructions at the link above. The installer should do its thing.

Completing the Installation:

You should notice a blue "HP" logo in the upper right-hand portion of your screen.

You MAY be prompted to reboot or log out, then log back in.

If that is the case, you will need to run a "hp-setup" command from the command line to finish the installation. If you are running Fedora, you may need to disable SE functionality again as you did above. At this point, a dialog window will appear. This is the configuration window for setting up your printer. You will see a form to enter the printer name, description, and location [office, lab, ...]. Your system will search for a driver and should automatically download what it needs.

Select the "Print Test Page" button - if all has gone right you should be rewarded with a printout of the HPLIP test page.

IMPORTANT Fedora SE LINUX settings for Printing

After installing HPLIP, you should go back into the "SE LINUX Administration" menu and reset the "Current Enforcing Mode" to "Enforcing". Failure to do this will leave your system vulnerable to attacks!

In order to keep SE LINUX's "Current Enforcing Mode" set to "Enforcing" and STILL BE ABLE TO PRINT, do the following: